This exhibit and article are courtesy of CHH member Gloria Chukman.

Looms come in all difference shapes and sizes, and there are many ways to obtain woven fabric. This exhibit showcases some of the many looms that are unusual or in some way unique compared to ones most of us today.

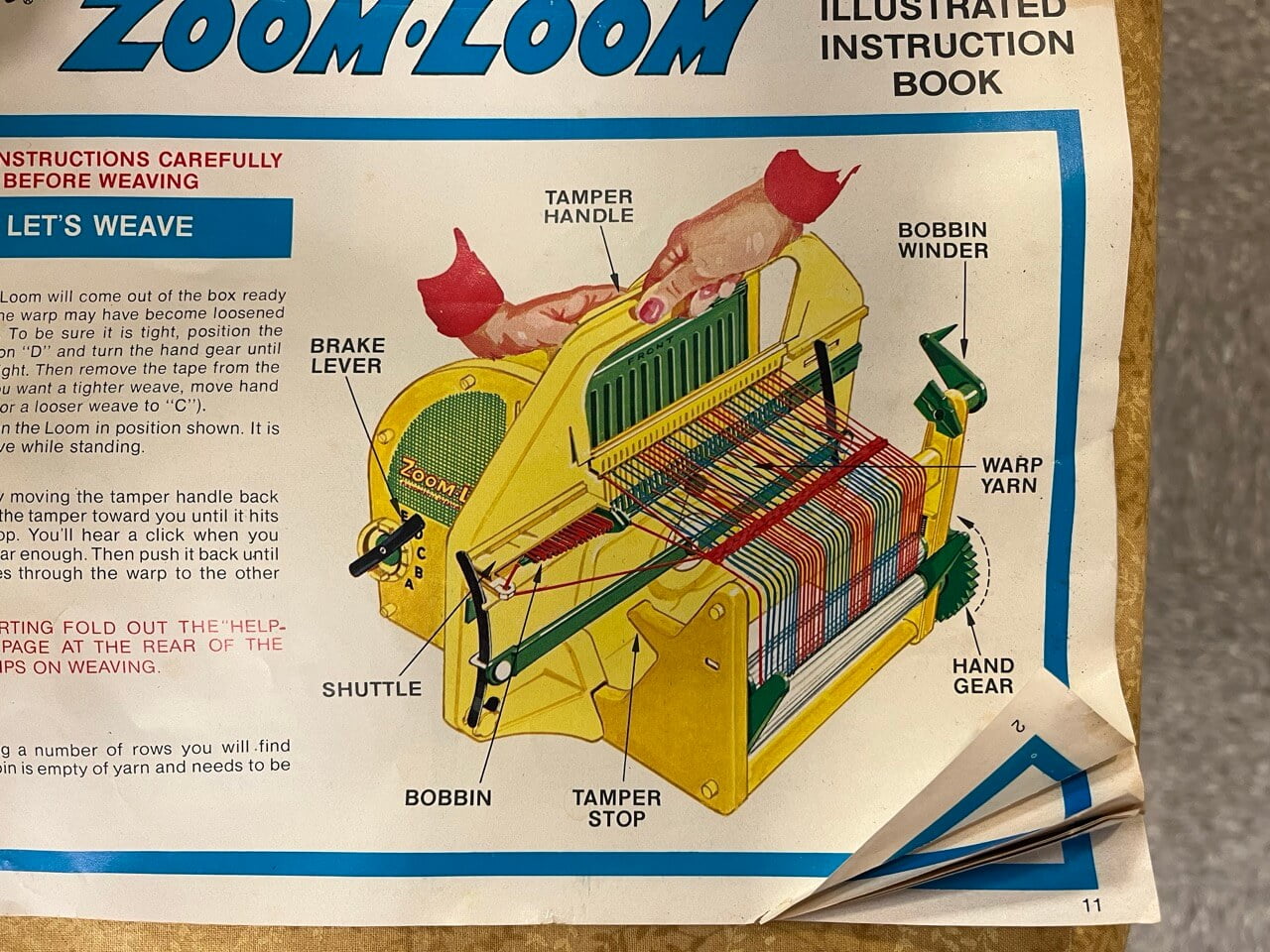

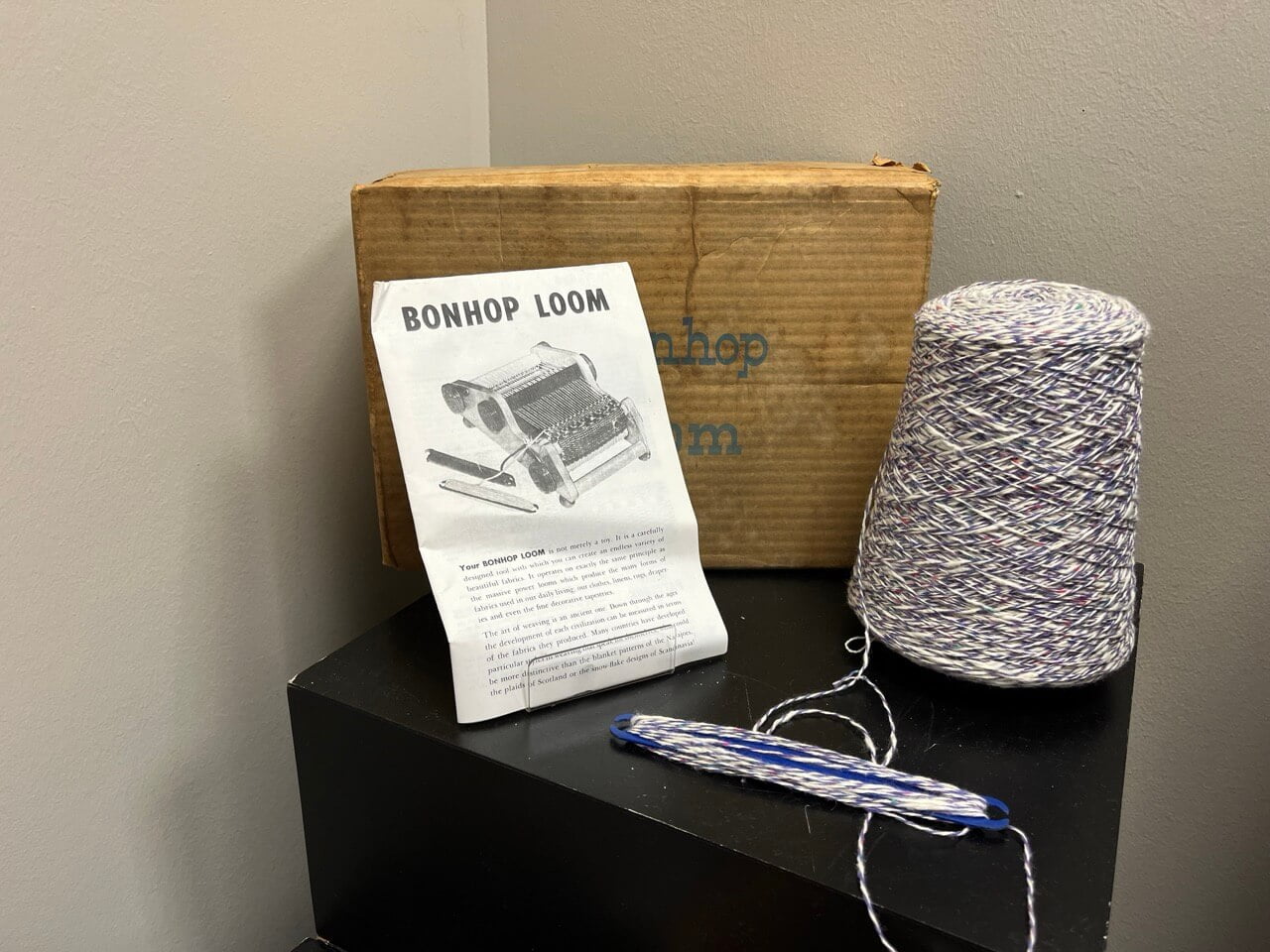

Some of these looms are built and marketed as toys, yet in many cases they are quite suitable for adult weaving as well. The Zoom Loom includes a flying shuttle, which helped increase speed on production looms from early in the industrial revolution. The Bonhop Loom, first manufactured in the 1950’s, indulges a heddle that requires no threading. This type of heddle has returned in popularity, marketed primarily for tapestry frame looms. Another special loom is a variety of traditional loom, design to easily weave around pegs, producing fabric which displays only the weft yarn and hides the warp yarn which is threaded through holes; the weaving regularly pulled down over the warp to advance.

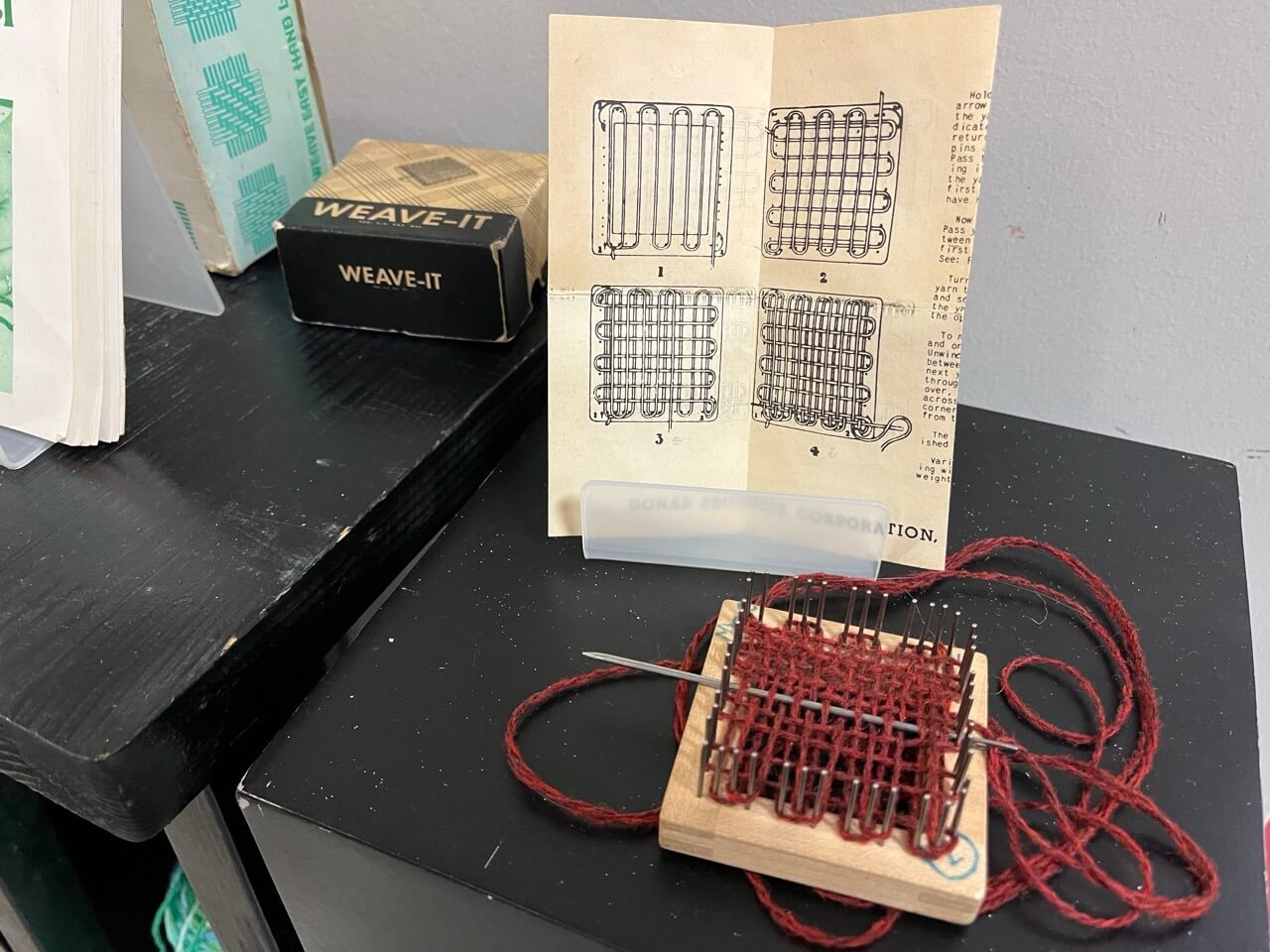

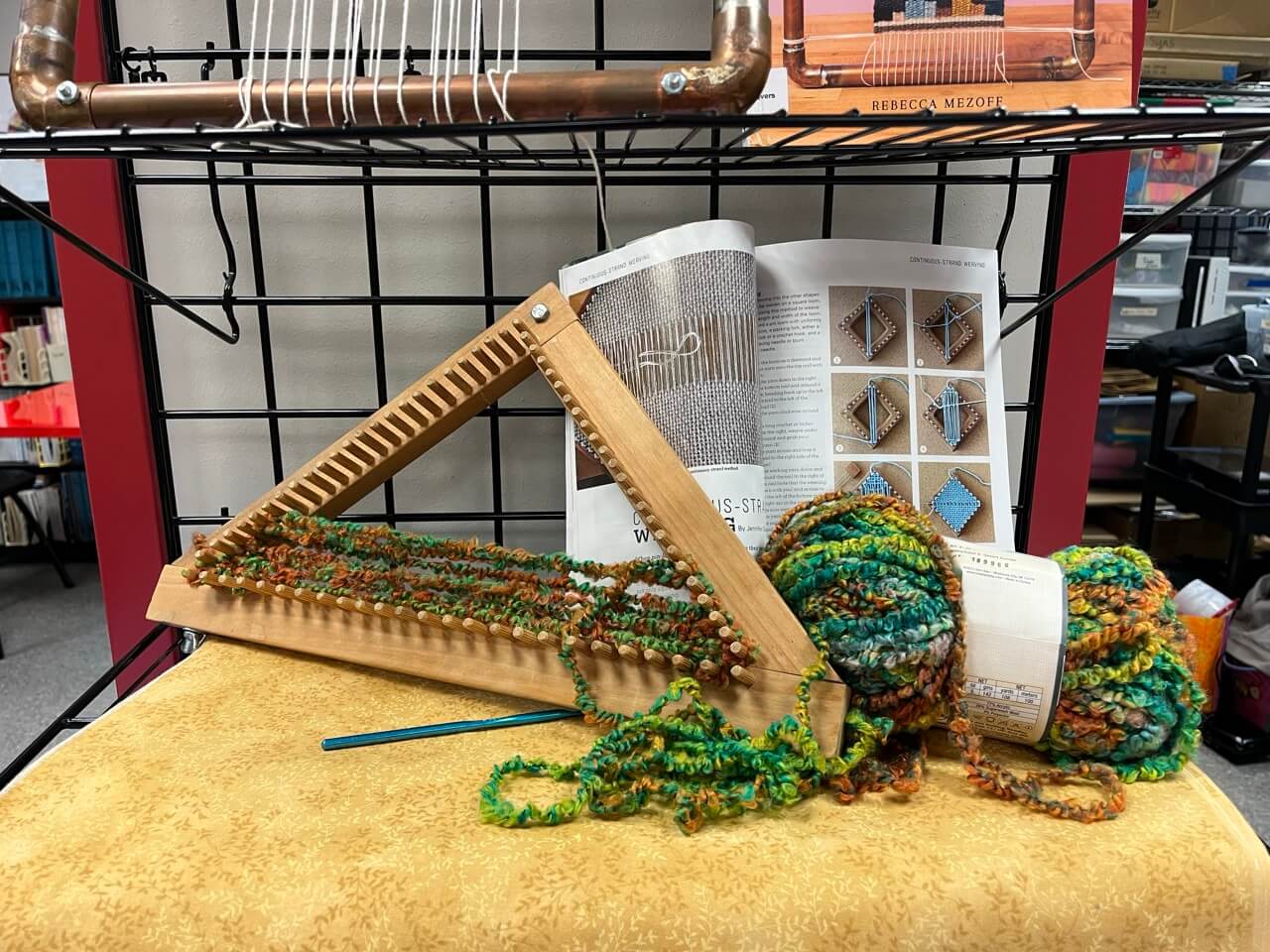

Looms that produce squares and triangles have been marketed to adults. These produce fabric pieces meant to be joined with others into larger objects. The Weave-It looms were patented in the 1930’s, and production was revived in the 90’s branded at Weavette. Triangle looms have been popular for several decades, and large ones can make a shawl. These looms allow weavers to use on continuous strand to weave the entire piece; yarn is not wound on a shuttle.

Two looms feature heddles that move side-to-side to create a shed, instead of the more typical up and down. These produce rectangles of fabric, and small versions of these have recently been selling as a method of decorative patching.

Of course, looms can be made of many materials. While wood is used for most looms marketed for adults, and plastic is often used for children, many materials are suitable for a loom. A popular do-it-yourself copper pipe tapestry loom was designed by Archie Brenner; he made the plans available to anyone. If following his original plans, like the loom displayed here, copper pipes are soldered together to create a frame loom. Nowadays, superglue like Gorilla Glue can be used to connect the parts. This loom includes screws to adjust tension as the weaving progresses; strands and heddle holders can be added.

This is exhibit is hands-on. Stop by the guild house in August and try out any of these looms for yourself! Instructions are near each one. Happy weaving!